Part 4: Problem-Solving Methodologies and Approaches

A Series on Problem Solving

Problem-solving is rarely linear. It is iterative, meaning each step loops into the next, allowing for feedback, adjustment, and continuous improvement. This cyclical nature is crucial because every solution typically generates new problems, requiring further refinement or intervention.

Clarifying Terminology: Approaches, Frameworks, and Methodologies

Approach: A broad philosophy or style of tackling problems. It may be high-level and conceptual or structured enough to guide detailed processes. Example: Human-centered design is an approach.

Framework: A structured outline or skeleton that provides a general guide to solving a problem. Frameworks are flexible and can be tailored to different contexts. Example: The GROW model or OODA Loop.

Methodology: A systematic set of rules and principles used to derive specific methods or techniques for solving problems. It is usually more detailed and prescriptive. Example: DMAIC, PDCA.

The progression also reveals why organizations sometimes struggle with implementation; they might adopt a methodology when they need an approach, or try to apply a rigid framework when they need flexible principles. Understanding these distinctions helps leaders choose the right level of structure for their specific context and organizational maturity.

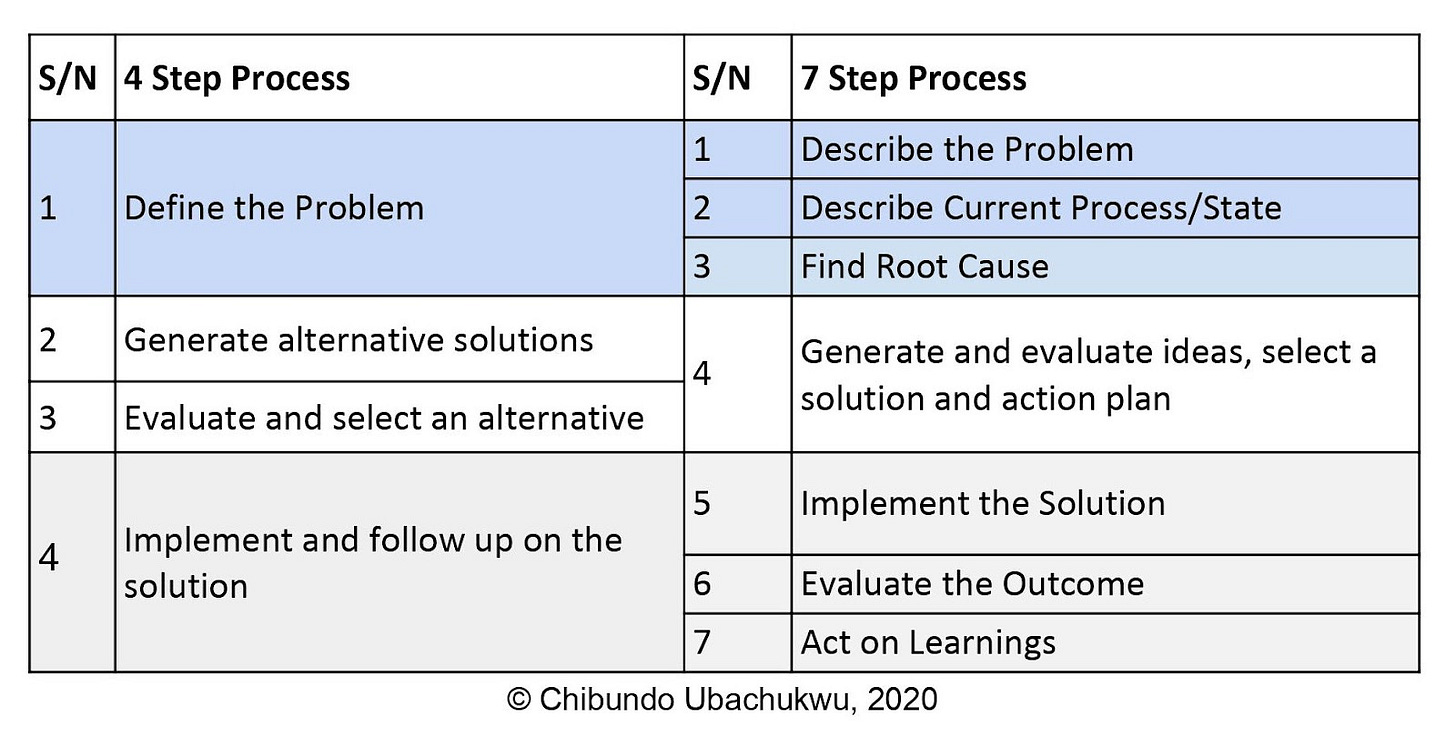

The Core Problem-Solving Process. Although specific methodologies may differ in terminology or emphasis, most build on the same fundamental steps:

Each step involves tools, techniques, and data-driven analysis to ensure decisions are sound and sustainable.

Many modern methodologies trace their roots to Total Quality Management (TQM), Six Sigma, and Lean Manufacturing, each developed in different contexts but widely adopted across industries.

1. Total Quality Management (TQM): Founded by W. Edwards Deming. TQM is a management philosophy that emphasizes continuous improvement, customer satisfaction, and process excellence. It holds that quality must be built into every part of the organization, and problems should be addressed at their root to meet or exceed stakeholder expectations.

2. Six Sigma: A statistically driven methodology that focuses on eliminating variation and improving process performance. “Six Sigma quality” indicates that a process is well controlled (fewer than 3.4 defects per million opportunities). And emphasizes the use of data, measurement, and statistical tools to improve outcomes.

3. Lean Manufacturing: Originating from Toyota, Lean emphasizes the elimination of waste (“muda”) to improve efficiency and value delivery.

The 8 types of waste (acronym: DOWNTIME) are: Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing.

4. Lean Six Sigma: A hybrid philosophy combining Lean’s focus on waste elimination with Six Sigma’s focus on variation reduction. It is fact-based, data-driven, and emphasizes standardization, flow, and customer satisfaction.

Popular Problem-Solving Methodologies

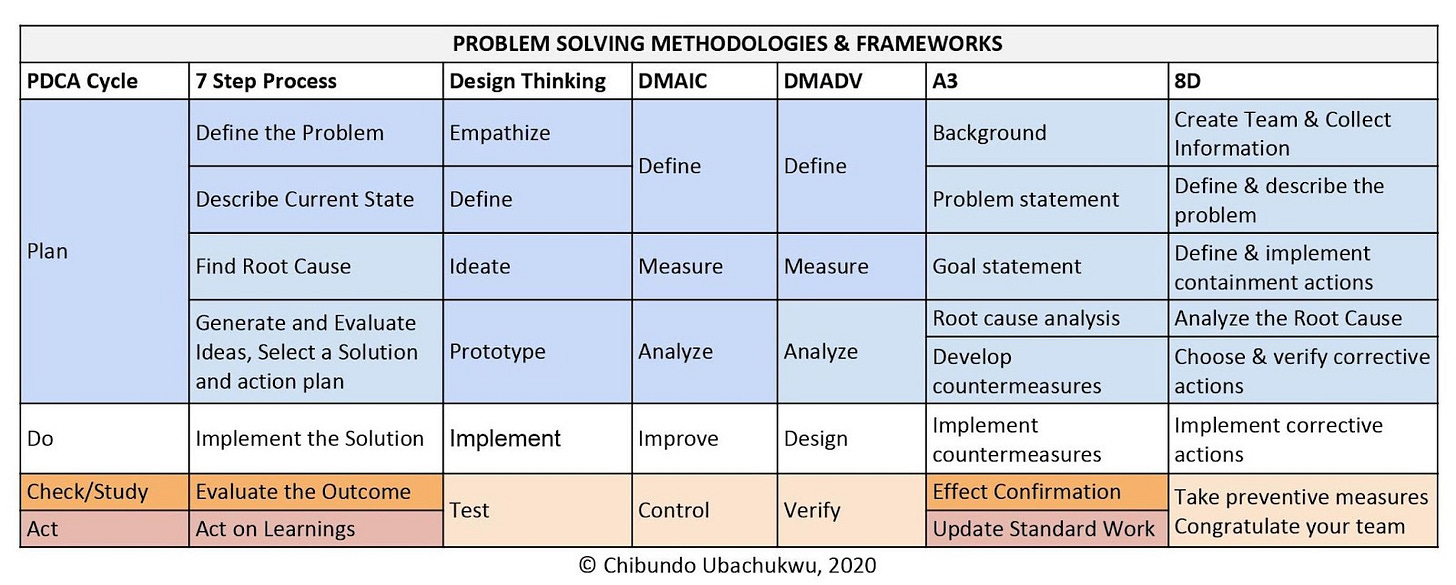

1. PDCA / PDSA Cycle: Plan – Do – Check (Study) – Act. An iterative loop for continuous improvement of processes, products, or services. Widely used in TQM and process management.

2. DMAIC (Six Sigma). Define – Measure – Analyze – Improve – Control. Used to improve existing processes. Heavily data-driven and structured, ideal for identifying root causes and implementing measurable changes.

3. DMADV (Six Sigma). Define – Measure – Analyze – Design – Verify. Used when designing new processes or products. Focuses on ensuring new systems meet customer expectations from the outset.

4. A3 Problem Solving (Lean): A structured template-based approach used by Lean practitioners (especially in automotive). Named after the A3-size paper used to present the problem, analysis, and solution concisely.

5. 8D Methodology (Ford Motor Company) - Eight Disciplines of Problem Solving: A structured, team-oriented approach designed to identify, correct, and eliminate recurring issues. Especially useful for root cause analysis and corrective action in manufacturing settings.

6. Design Thinking: A human-centered, iterative methodology that seeks to understand the user deeply, challenge assumptions, and prototype solutions rapidly.

Phases include:

Empathize

Define

Ideate

Prototype

Test

It is widely used in innovation, UX/UI, education, and organizational design.

Niche Approaches

For highly specialized contexts, the following models may be valuable:

GROW: Used in coaching and personal development.

OODA Loop: Effective in chaotic or ambiguous settings (e.g., startups, crisis strategy).

TRIZ: Powerful in R&D, engineering, and technical innovation.

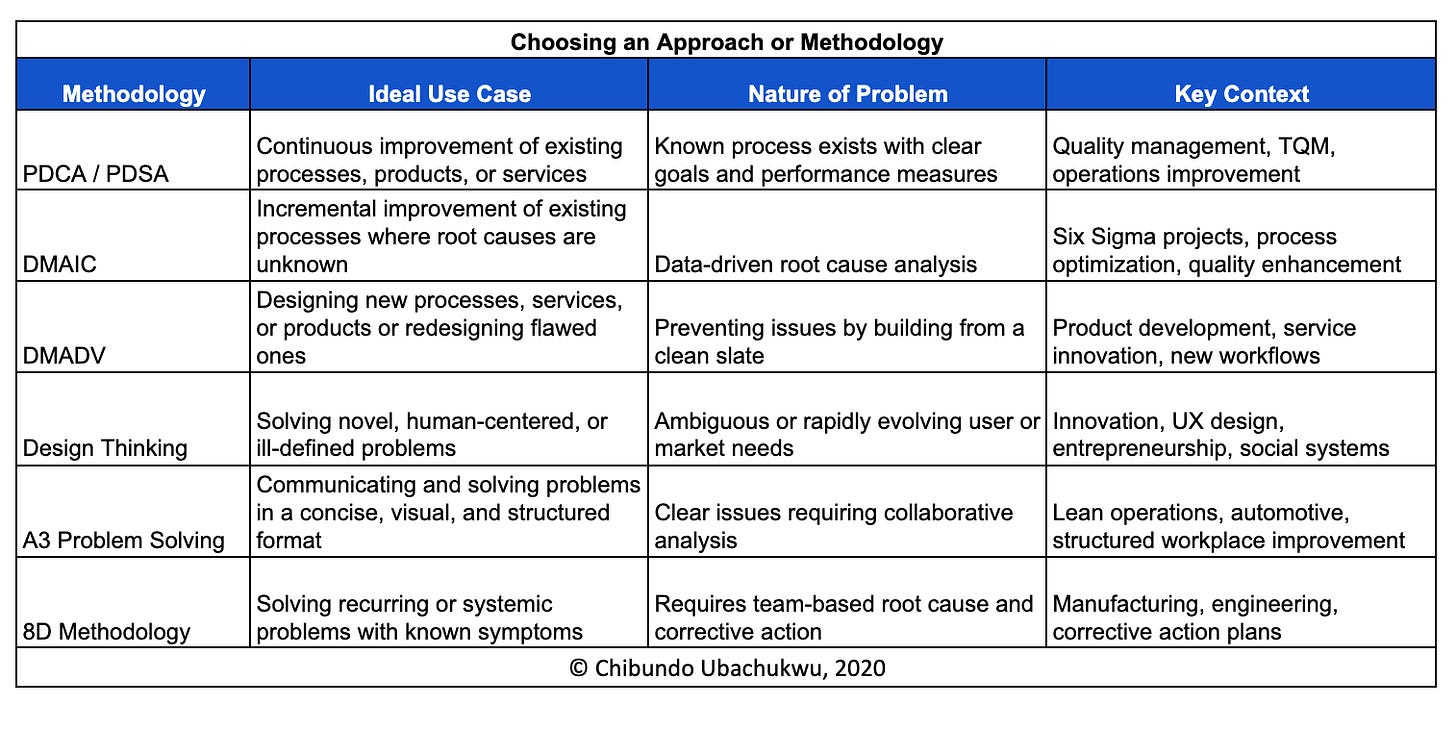

There is no one-size-fits-all methodology. The key is to:

Understand your problem type and context

Select an appropriate framework or methodology

Apply it consistently while allowing for flexibility

Learn from each iteration and adapt as needed

The next table is a guide on how to choose what works for you.

Great problem solvers don’t just act, they adapt. They don’t just fix, they transform.